HVAC Safety Tips & Checklist | How SWMS Automation Can Help You

How dangerous is HVAC? ( 9 Safety Hazards To Know)

The HVAC industry can be vey reading at times. However, without proper protocols in place, you can be at risk of safety hazards in the workplace.

A key part of HVAC maintenance for any HVAC or field service business is ensuring that everything is in proper working order. Here are the top 9 safety hazards you need to know:

Dangerous Chemicals

As one of the most common hazards in the workplace, dangerous chemicals are a risk that can be found on most work sites. Chemical exposure to potential hazards such as cleaning liquids and gas cylinder refrigerants were found to be the most common on HVAC worksites. Chemical refrigerants when handled incorrectly can lead to burns and serious injuries.

2. Respiratory Dangers

A major health risk for HVAC technicians is respiratory risks. Carbon monoxide poisoning, mould inhalation and asbestos exposure are just some of the risks that technicians can come across. When working with old units or working in enclosed spades, you can become more likely to be exposed to harmful respiratory hazards. The best prevention method is always using the correct masks or face shields.

3. Electrical Equipment Safety Hazards

It won’t come as a shock to you to know that electrical hazards are a major contributor to technician injuries. A simple mistake like forgetting to de-energize equipment before a job, could lead to serious injury. With risks of high voltage sites and electric shock, you need to ensure your team is briefed in the correct electrical protocols.

4. Heights & Ladders

Nearly 85% of falls on the worksite included a ladder, latest studies show. The most common mistakes when concerning ladders were due to a lack of precaution. Taking the time to safely secure your scaffolding or ladder could be the difference between going home on time at the end of the day and ending up in the emergency room. Remember to always use the 3-point rule when using ladders at all times.

5. Hazardous Driving

Hazardous driving is a major cause of death and injury both in and out of the workplace.

Speeding to make up for lost time is never a safe option. Most HVAC companies will involve driving from site to office on a daily basis and it is important that you ensure your technicians are being safe on the road. Not only will driving dangerously risk accidents, but it can also reflect badly on your business. No one wants to hire the car that just cut them off in traffic to fix their plumbing.

H3: 6. Hazardous Weather Conditions

HVAC technicians have to work inside and out year round and extreme temperatures can be a hazard to personal safety. The outside work environment conditions can lead to injuries such as heat stroke, hypothermia and fatigue. Remember to always exercise caution and stay hydrated in extreme heat and wear proper clothing in colder conditions.

7. Faulty or Missing Equipment

In your inventory of equipment you need to ensure that electrical equipment follows tag procedures and your equipment is routinely serviced or checked. Not only will making an inventory of your equipment keep you safe, it will also save time on your next job.

8. HVAC Technicians & A Lack Of Training

You may have all your equipment tagged and tested, all your assets properly maintained and the right PPE, but do you team have the proper safety training?

Taking the time to teach your employees can help reduce the chase of accidents in the workplace.

9. Health Regulations

Taking the necessary precautions also applies to health regulations like COVID-19. When possible it is recommended that customers and technicians say at least 1.5m away from each other and wear face masks where applicable.

Want to know what happens when you don’t pay attention to safety? Check out the 9 Construction Accident & Safety Statistics you should read in 2021 to learn more.

Top HVAC Safety Tips You Should Know

The HVAC Industry in 2021 is a lot different to what the industry looked like 50 years ago. With the evolution of work methods, introduction of more high powered equipment and technological advances, there has also come an increased risk in the workplace.

When dealing with heavy equipment, harmful substances and hazards on site for extended periods, you need to know the correct safety procedures. Here are the top 7 safety standards you need to know:

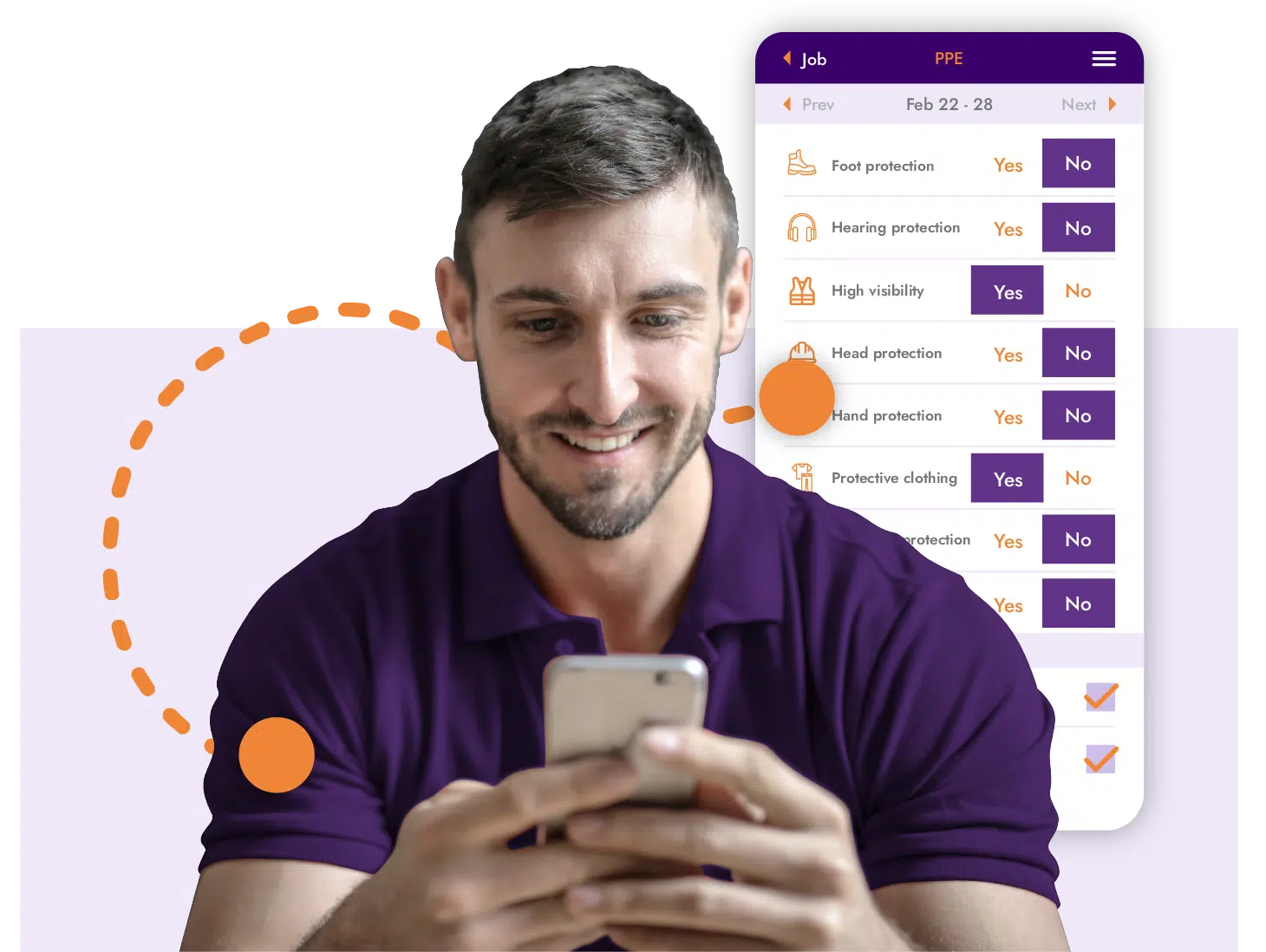

1. PPE is Key!

Having the correct PPE (Personal Protective Equipment) and protective gear while on site is vital to ensuring your technicians are keeping safe. The proper equipment and safety gear will not only reduce or eliminate safety hazards, but it will also reduce the risk of liabilities on site.

To help reduce safety risks, you can wear protective gear such as:

- Dust Mask

- Face shield

- Respirator

- Earplugs/earmuffs

- Eye Protection (Safety glasses)

- Fall Protection

- Fire Extinguisher

- Gloves

- Hard Hats

- Hearing Protection

- Hi Visibility Vests or Clothing

- Protective Clothing

- Work boots (including when necessary slip resistant shoes)

- Sturdy footwear with rubber soles must be worn

- Sunscreen must be worn

2. Know the Risks

As a part of training your HVAC technicians, you need to ensure that they know the risks of the equipment they are handling and the hazards they may be exposed to. Half of the battle when safety is concerned is with knowledge. A technician is less likely to be harmed or injured if they know the risks and safety procedures.

4. Ensure Your HVAC Technician Avoids The Shortcuts

We all use shortcuts at times, but there are times and places where shortcuts become more dangerous than simply doing it the right way. Cutting corners when it comes to safety could result in missing fingers, burns and a trip to the emergency room.

Procedures were developed for a reason and they are designed to ensure that technicians follow them. To avoid costly liability suits, emergency room trips and damaging equipment, it’s always better to stick to the procedures.

5. Keep Your Job Site Clean and Tidy

The best way to stop someone injuring themselves from a slip, trip or fall, is to keep a tidy workplace. Proper protocols should include risk assessments and procedures for your site. Some common hazards could include; slippery floors, chemical exposure, electrical wiring or faulty equipment.

6. Display the Correct Signage On Your Site

Signage is an important part of reducing workplace accidents. ‘High voltage’, ‘caution wet floor’, ‘dangerous chemicals’ or ‘PPE required’ signs all help to reduce the risk of injuries. Sign safety precautions can also help to reduce the risk of liabilities and lawsuits if an accident occurs.

How SWMS Automation Can Help You

What is a SWMS document? How can automation help your HVAC business run Safety protocols better?

Safety is vital for any business and especially for those where the risk of harm is greater by the nature of the work they do; ie handling electricity, high pressure, working at heights etc. With the assistance of automation you can not only ensure your team is safe but save valuable time in administration and follow up as well as manage compliance (document retention).

A SWMS has basic information like date, address of site and signatures of those involved to ensure compliance with correct procedures. While a SWMS document can help avoid hazards, sometimes filling out lengthy paperwork and chasing up signatures can be more painful than falling off a cherry-picker because you didn’t wear a safety harness. When you choose to automate your SWMS job workflow you can dynamically build the profile whilst at the site.

A SWMS document has a number of sections that are the core managing safety. Many SWMS documents are mandated in legislation and are highly technical documents and there are often variations specific to each project/site that can make them very cumbersome to maintain.

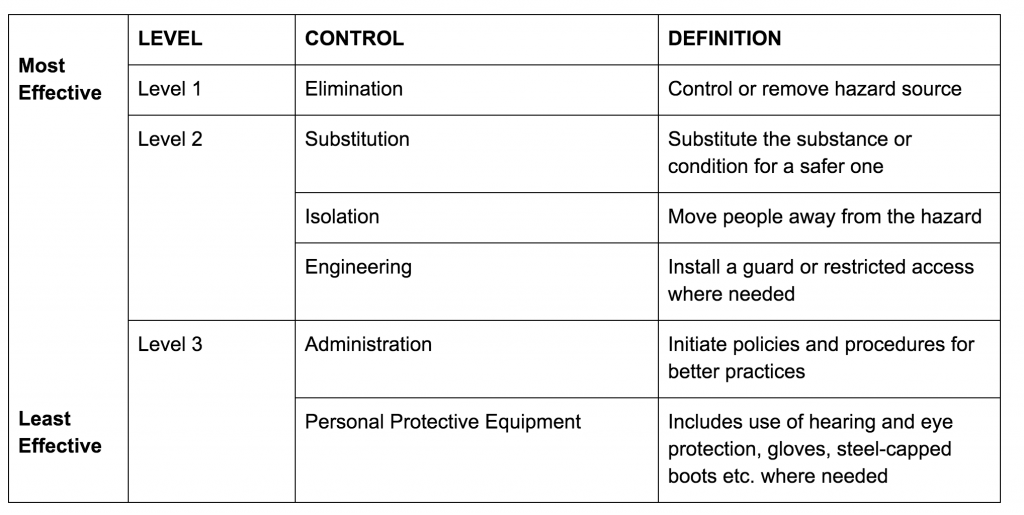

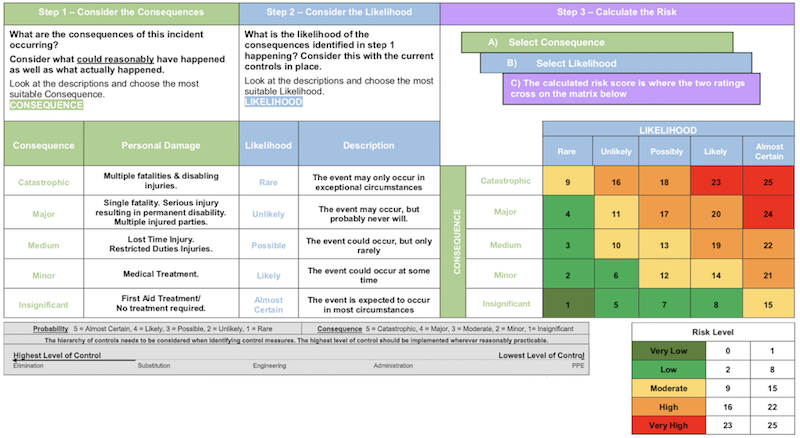

A control

A control system is used to manage the risk. There can be various ways to control the risk, as seen in the table below each control contributes to reduce the hazard to minimise or eliminate risk.

Hierarchy of Control

A Risk Matrix

A Risk Matrix will present a risk rating with a reference to the Risk Consequence and Risk Likelihood. These activities cover but are not limited to:

- Access to ceiling space via ladder

- Access to ceiling space via lifting equipment

- Installing new ceiling mounted units

- Running cables through existing ceiling space

- Run pipework through existing ceiling space

- Cutting copper pipe with tube cutter

- Welding copper tube

- Cut plasterboard using a keyhole plasterboard saw

- Install ceiling registers

- Install flexi-duct work and zone motors in ceilings space

- Connect new calves into electrical plant/ equipment

- Refrigerant charge the system using a vacuum pump

- Connect pressure pump

- Test the electrical installation

- Fill out and issue electrical certificate of compliance

- Cleaning up work area

- Vacuum

Risk Matrix

All of this can lead to extensive paperwork to ensure the safety of everyone on site. A technician can have a very rewarding job but when there is so much yellow tape around a construction site and so many hazards hiding in every corner, it can make life difficult.

Some of the challenges associated with paper based SWMS

- It can be annoying to have to keep track of a paper based SWMS register by site, project, technician etc

- SWMS paper registers can get lost

- SWMS can get damaged, ripped or smudged

- It’s hard to annotate and read the writing on a document that has been around the tracks

- It can be hard to edit and update an activity on a big SWMS document when new hazards arise or the situation changes frequently

Considering all of the difficulties, imagine how much easier life could be if you could:

- Grab any of your SWMS templates in the field when you want them

- Able to add protocols, steps and activities in a few minutes without having to grab a new form

- Able to capture your team’s signatures on the job and have that on your SWMS PDF to email to a customer or auditor immediately

- Have your SWMS on hand and have access to your documents without the hassle of calling the office.

Being able to access multiple SWMS templates or to edit SWMS on site are just some of the automation benefits that cut unnecessary admin and improve compliance. These are key features to FieldInsight’s automated software to increase productivity, safety and efficiency within your HVAC business. How does SWMS and checklists Improve your team’s safety?

How does SWMS and checklists Improve your team’s safety?

Safety

On any high risk construction site, PPE is an important safety measure for individuals. PPE safety measures can include:

- Dust Mask

- Eye and Hearing Protection

- Eye Protection

- Fall Protection

- Fire Extinguisher

- Gloves

- Hard Hats

- Hearing Protection

- Hi Visibility Vests or Clothing

- Protective Clothing

- Safety Boots

- Sturdy footwear with rubber soles must be worn

- Sunscreen must be worn

One of the biggest challenges on a HVAC site is paperwork compilation and the admin that goes with it. With a high rate of HVAC businesses using paper based systems, there can be a lot admin work for you and the office. When a HVAC business incorporates an automated software, more time can be spent on safety activity than time-consuming admin work. This shift from admin to safety can focus your time on assessing hazards and adding appropriate measures with very minimal office effort.

Regulatory compliance

A challenge that accompanies high risk work environments is opening yourself up to being sued. A common problem is technicians simply forget to complete their safety documentation. It can be as easy as getting a phone call or talking to a customer and getting distracted and forgetting to complete the paperwork.

A checklist can be a vital tool when you consider all that can go wrong on site. By having a checklist you can ensure your technicians won’t miss any steps or protocols. With an automated system, you can enforce SWMS compliance and see when your technicians have completed their checklist. Having an automated system that supports safety documentation goes a long way to showing that you are committed to safety.

Don’t wait until an auditor comes to site and finds mistakes on your SWMS documentation (hopefully the visit by worksafe isnt because of a reported accident). By having a workflow oriented checklist in place you can make safety easier for all your team.

Streamline safety systems

A big deterrent in safety documentation, SWMS and JSA can be the complexity and time consuming nature of paperwork. The key to managing paperwork is having a flexible system where you can build SWMS documents into editable templates that your technicians can modify as they need in the field. No two workplaces are the same and you need the flexibility to modify whilst on site and not run back to the office to complete a new document (and hopefully not forget anything).

With FieldInsight, you can manage versions and your technicians can access templates and checklists without calling the office. With increased efficiency you can dramatically improve the ease of compliance and reduce admin effort. Your team can also get on to completing the job and save you paying them to sit around and wait for a document to be finalised.

Having this at a glance you can see the jobs that have been done for the day and check all SWMS have been signed. This level of visibility means increased efficiency for the whole HVAC team.

People make mistakes

No one intentionally enjoys risking their life or limb, but people make mistakes. Having extra guidelines by incorporating a checklist can reduce human error and have a profound impact on safety outcomes.

When a technician has been working since sun-up and they are tired or distracted at the wrong time, it can be easy to make a mistake. Remember that safety awareness goes up significantly with checklists. Not only can you lose customers over simple mistakes on site but it can also open you up for legal risks. For the same reason that a surgeon or a pilot will use a checklist, your technicians need to be considering the safety of themselves and those around them. Don’t let simple errors be the failing of your business.

How can FieldInsight help improve safety in your HVAC business?

With the amount of hazards present on site, you can’t risk your team’s safety. Something as little as forgetting to switch off the power can cause an avoidable mistake and possible harm.

What’s grey, frayed and hanging from the ceiling? A technician who didn’t complete his SWMS to include this before checking the wires on an air conditioning unit could be catastrophic.

Ensure your team is practising safe work measures and increase productivity by incorporating a Job Management Software into your HVAC business.

What You Should Do Now

- Book a Demo. You’ll be in touch with an automation expert who has worked in this space for over 5 years, and knows the optimal workflow to address your needs.

- If you’d like access to free articles about managing HVAC workflows, go to our blog.

- If you know someone who’d enjoy reading this page, share it with them via email, Linkedin, Twitter, or Facebook.