Navigating Plumbing Asset Maintenance: A Guide for Future-Ready Plumbers

The rising need for proactive asset maintenance has become a critical aspect of modern plumbing operations. As plumbers strive to strike the delicate balance between ensuring the longevity of their tools and delivering top-notch services, the role of effective asset management has taken center stage. This guide aims to provide plumbers with insights and strategies for navigating the complexities of plumbing asset maintenance, ensuring they are well-equipped to meet the demands of the digital age.

The Pillars of Effective Plumbing Asset Maintenance

1. Cataloguing Equipment: The Foundation of Understanding and Tracking

At the heart of a robust maintenance strategy lies a comprehensive understanding of your plumbing tools and machinery. By creating a detailed catalog of all your assets, you gain the ability to track their usage, maintenance history, and potential issues. This foundational step paves the way for informed decision-making and ensures that no equipment is overlooked when planning maintenance routines.

2. Routine Health Checks: Advantages of Habitual Inspections

Regular health checks for your plumbing tools are akin to preventive healthcare for humans. Just as early detection of health issues can prevent serious complications, routine inspections can identify potential problems with your equipment before they escalate. By implementing scheduled checks, you not only extend the lifespan of your tools but also minimize downtime caused by unexpected breakdowns.

3. Analytical Decision Making: Leveraging Data for Proactive Maintenance

Data-driven decision-making is a cornerstone of modern business practices, and plumbing asset maintenance is no exception. By collecting and analyzing data on equipment performance, usage patterns, and maintenance history, plumbers can make intelligent decisions about when to perform maintenance, replace components, or upgrade tools. This approach shifts maintenance from a reactive stance to a proactive one.

4. Safety Protocols: Efficiency and Safety Go Hand in Hand

Maintaining plumbing tools isn’t just about keeping them operational; it’s also about ensuring the safety of plumbers and clients. A well-maintained tool is less likely to malfunction during a job, reducing the risk of accidents. Incorporating safety protocols into your maintenance routines not only safeguards everyone involved but also reflects your commitment to delivering quality workmanship.

The Digital Age: Using Technology in Plumbing Asset Maintenance

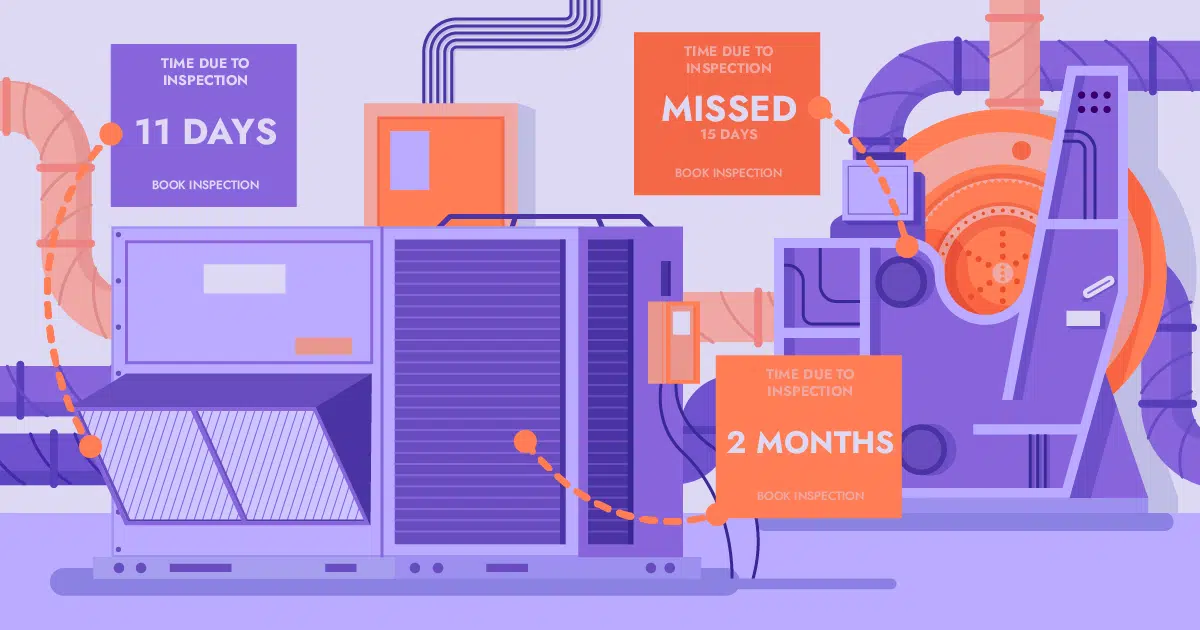

1. Maintenance Reminders: Streamlining with Digital Tools

Modern technology offers a plethora of tools to automate various tasks, including maintenance scheduling. Implementing digital solutions can help you set up automated reminders for routine inspections and maintenance tasks. This ensures that maintenance activities are never overlooked and that your assets receive timely care.

2. Predictive Over Reactive: Harnessing Technology for Foreseeable Failures

Predictive maintenance is a game-changer in the plumbing industry. By leveraging data analytics, sensors, and predictive algorithms, plumbers can anticipate potential equipment failures before they happen. This approach not only minimizes disruptions to your workflow but also reduces the cost associated with emergency repairs.

3. Unified Equipment Database: The Power of Centralized Digital Databases

In the digital age, information is your most valuable asset. Centralizing all equipment-related data in a digital database streamlines the maintenance process. Accessible to all team members, this database provides a single source of truth for asset information, maintenance history, and upcoming tasks.

Navigating Challenges in Plumbing Asset Maintenance

1. Cost Analysis: Balancing Repairs and Replacements

One of the challenges in asset maintenance is striking the right balance between the cost of repairing equipment and the cost of replacing it. A thorough cost analysis for each scenario can help you make informed decisions that align with your budget and long-term goals.

2. Keeping Up With the Times: Adapting Maintenance Strategies

The plumbing industry is constantly evolving, with new tools and technologies entering the market. To stay competitive, plumbers must adapt their maintenance strategies to accommodate these changes. Regularly evaluating and updating your approach ensures that you’re not left behind.

3. Efficiency Metrics: Measuring the Effectiveness of Maintenance

Establishing key performance indicators (KPIs) allows you to measure the success of your maintenance efforts. Metrics such as equipment uptime, repair frequency, and overall job efficiency can provide valuable insights into the effectiveness of your strategies.

Comprehensive Planning Tips for Successful Asset Maintenance

1. Setting Clear Goals: Defining Measurable Objectives

Effective asset maintenance begins with clear goals. Set measurable objectives that align with your business objectives, such as reducing downtime, improving safety, or extending equipment lifespan. These goals serve as a compass for your maintenance activities.

2. Asset Prioritization: Identifying Critical Tools

Not all tools are created equal when it comes to maintenance priorities. Identify critical tools that are essential to your operations and require more frequent or specialized care. By allocating resources strategically, you ensure that your most important assets are always in optimal condition.

3. Budget Forecasting: Allocating Resources Wisely

Maintaining a budget for asset maintenance is crucial. Anticipate both routine and unforeseen maintenance needs and allocate financial resources accordingly. This proactive approach prevents financial strain and allows for seamless maintenance activities.

4. Timelines & Scheduling: Structured Maintenance Calendar

Develop a structured maintenance calendar that covers short-term and long-term activities. This timeline ensures that routine inspections, predictive maintenance tasks, and major overhauls are all accounted for, minimizing disruptions to your workflow.

5. Staff Training: Fostering Collective Responsibility

Effective maintenance is a collaborative effort. Educate your teams on the importance of maintenance practices and provide training on how to perform routine checks. Fostering a sense of collective responsibility ensures that everyone is invested in maintaining the tools they use.

6. Feedback Loop: Involving Staff in Proactive Maintenance

Encourage staff to report tool issues and anomalies they encounter during their work. Implement a feedback loop that allows for timely intervention and addresses potential problems before they escalate. This proactive approach prevents larger issues down the line.

7. Continuous Evaluation: Adapting to Real-World Outcomes

Maintenance strategies are not set in stone. Regularly evaluate the effectiveness of your approach based on real-world outcomes and evolving industry standards. Make adjustments as needed to optimize your maintenance efforts.

The Direct Impact of Asset Maintenance on Plumbing Jobs

Minimized Interruptions:

Proactive asset maintenance leads to fewer work stoppages. When tools are consistently maintained, the chances of unexpected breakdowns during critical plumbing tasks decrease significantly. This seamless workflow translates to improved project timelines and customer satisfaction.

Quality Service:

Well-maintained tools are the backbone of delivering quality service. Functional equipment allows plumbers to perform tasks efficiently and with precision, resulting in reliable solutions for clients. The direct correlation between equipment maintenance and service quality cannot be overstated.

Building Clientele Confidence:

In the competitive plumbing industry, client trust is invaluable. Consistently reliable tools create an aura of professionalism that instills confidence in your clientele. When clients know they can rely on your well-maintained equipment, they’re more likely to become repeat customers and refer your services to others.

Key Takeaways for Plumbing Asset Management

In the realm of plumbing, methodical asset maintenance stands as a cornerstone of success. The proactive approach to keeping tools and equipment in prime condition isn’t just a technical practice—it’s a strategic move that elevates the efficiency, safety, and quality of your plumbing operations.

Embracing technology in the form of asset management software and job management tools streamlines maintenance tasks, transforming them from burdensome obligations to automated and informed decisions.

Are you a service manager looking to revolutionize how you manage your field service business? Say goodbye to manual processes and wasted time. Experience the power of FieldInsight software—a comprehensive solution designed to optimize your operations, enhance efficiency, and elevate customer satisfaction.

With FieldInsight, you can effortlessly schedule jobs, assign tasks to your team, and track progress in real time. Our intuitive platform simplifies communication, automates repetitive tasks, and provides valuable insights that empower you to make informed decisions.

Join the ranks of successful service managers who are already reaping the benefits of FieldInsight. Boost your productivity, save time, and take your business to new heights. Get started today and unlock the full potential of your field service operations.

Ready to transform your business?

Schedule a discovery call today!

What You Should Do Now

- Book a Demo. You’ll be in touch with an automation expert who has worked in this space for over 5 years, and knows the optimal workflow to address your needs.

- If you’d like access to free articles about managing HVAC workflows, go to our blog.

- If you know someone who’d enjoy reading this page, share it with them via email, Linkedin, Twitter, or Facebook.